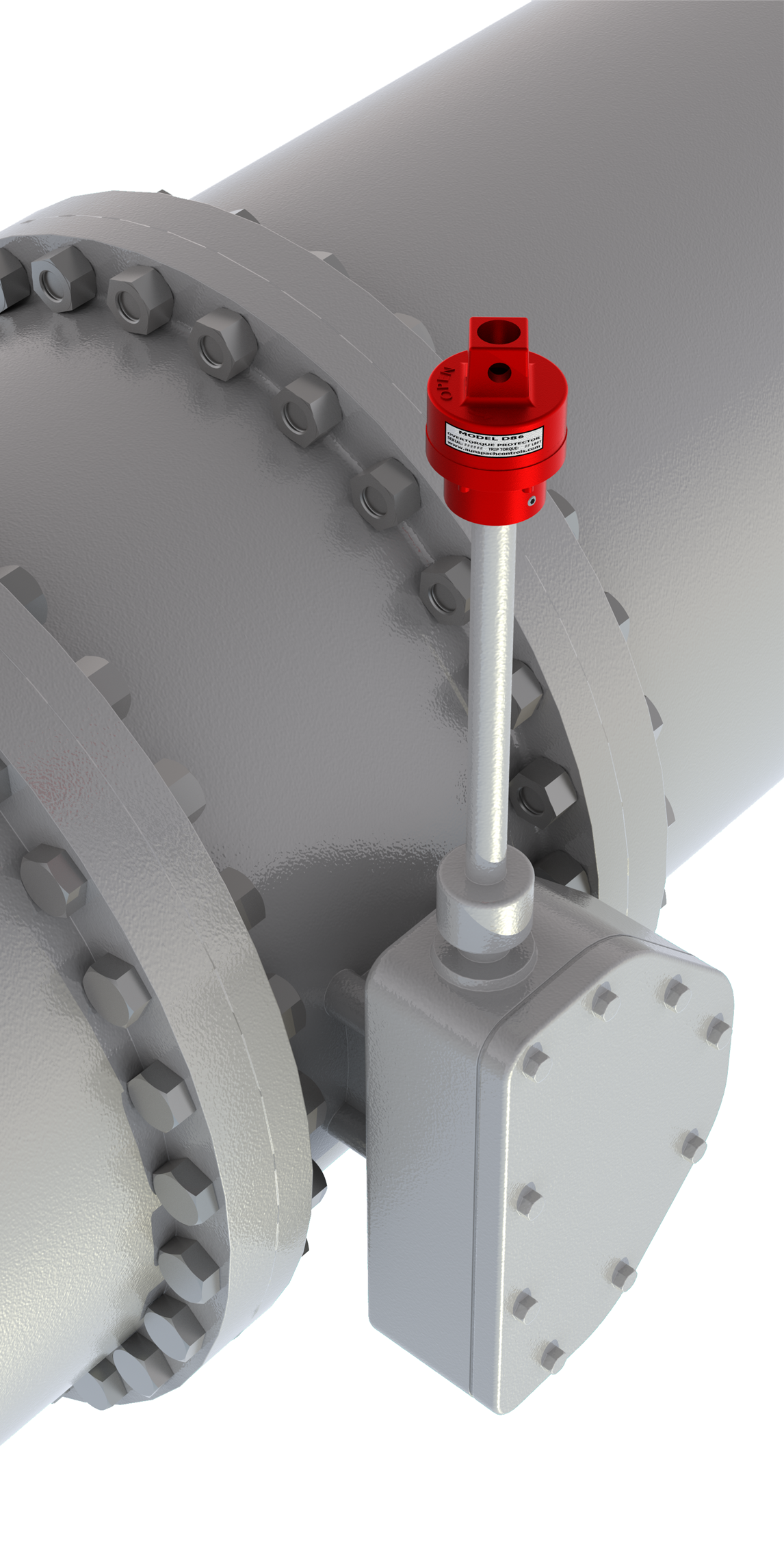

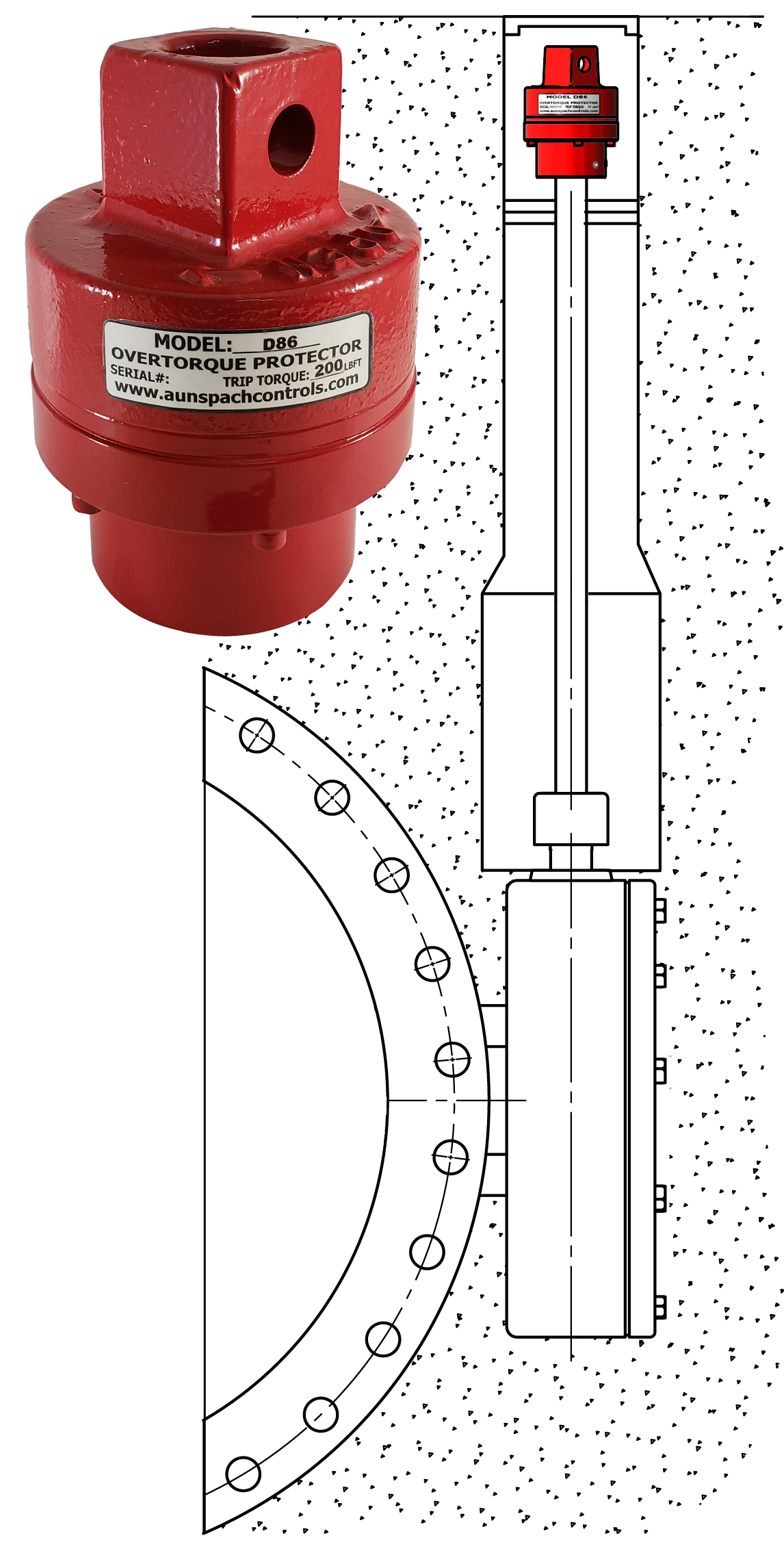

Model D86

AWWA Valve Overtorque Clutch

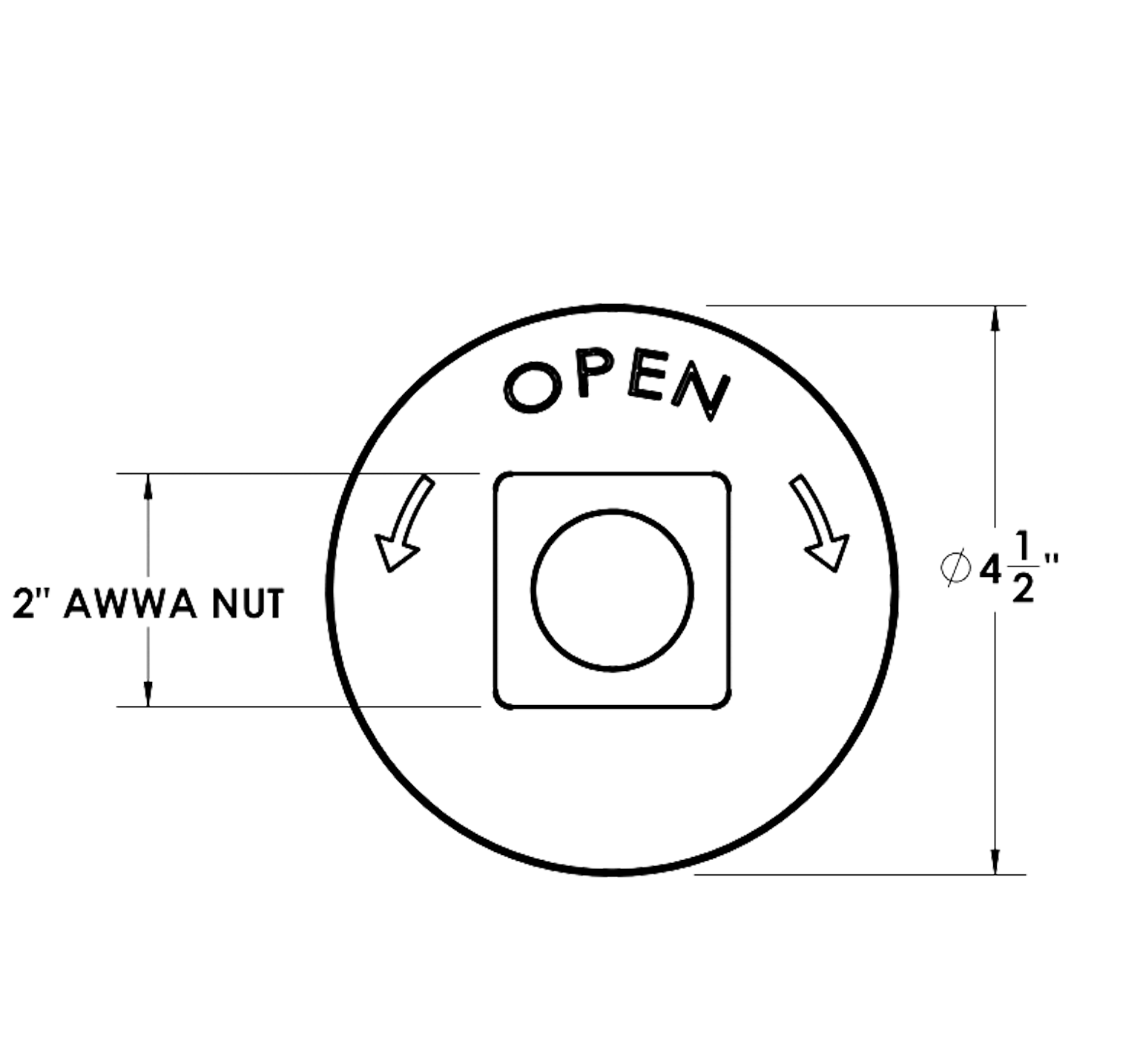

The Model D86 Valve Overtorque Protector ™ is permanently mounted on the valve operating nut. No special tools or valve modifications are required. It’s easily mounted on direct buried valves without excavation. Operating torque is applied to the 2-inch AWWA nut on the Model D86 then transmitted through the D86 to the valve. The Model D86 will transmit sufficient torque to free up and operate the valve. If excessive torque is applied, the drive will disengage and prevent valve damage. The drive will automatically re-engage at the original setting with further rotation in either direction.

Features

- ZERO maintenance

- Operates buried and submerged

- Permanently lubricated, hermetically sealed mechanism

- Corrosion protected inside & out with AWWA C213-approved fusion-bonded epoxy & stainless-steel fasteners

- Exceeds IP68 water ingress standard. Tested water-tight under 230 feet water pressure.

- Pre-calibrated & ready to mount, no modifications required

Specifications

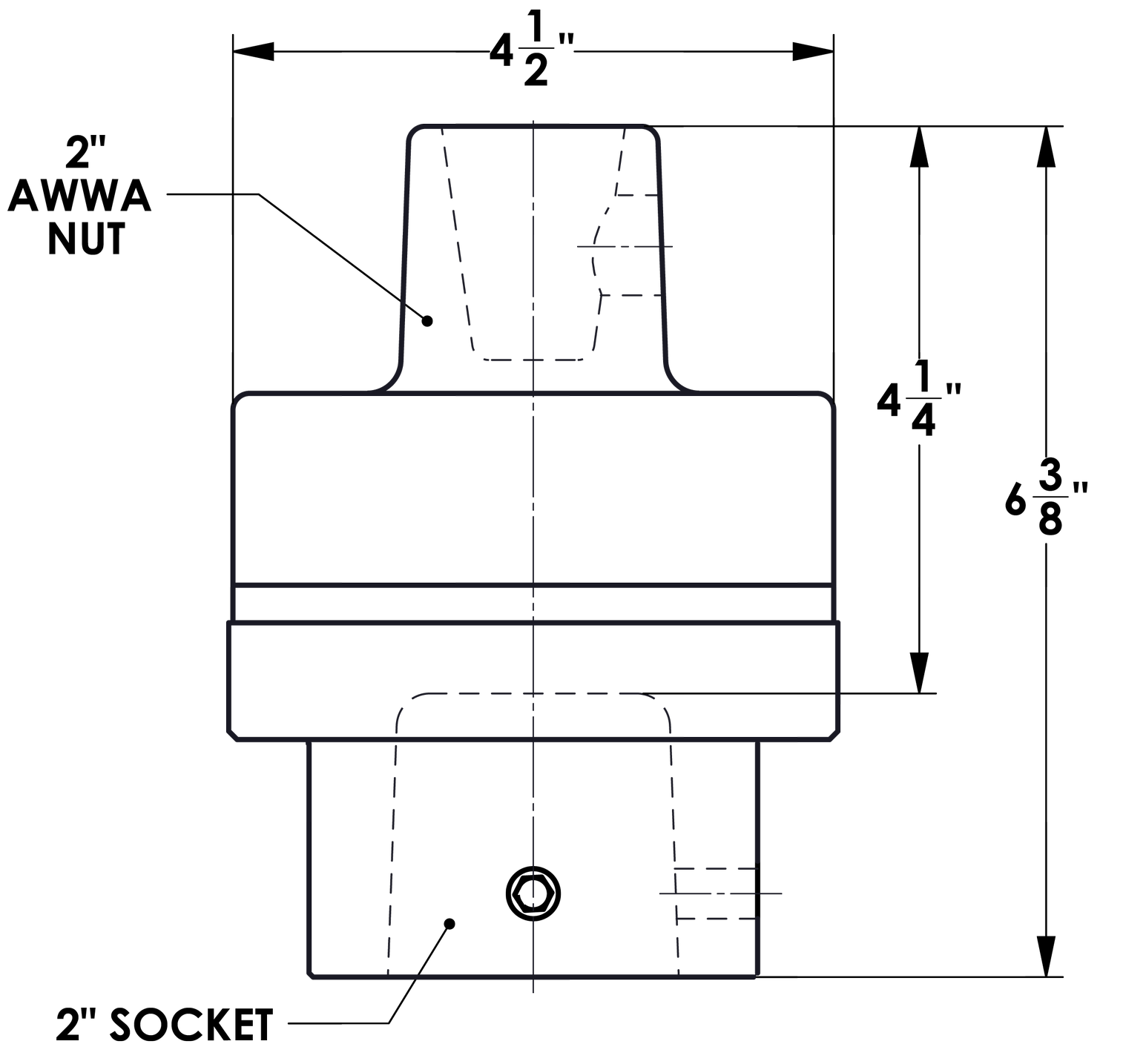

- Male Connection: 2" AWWA operating nut

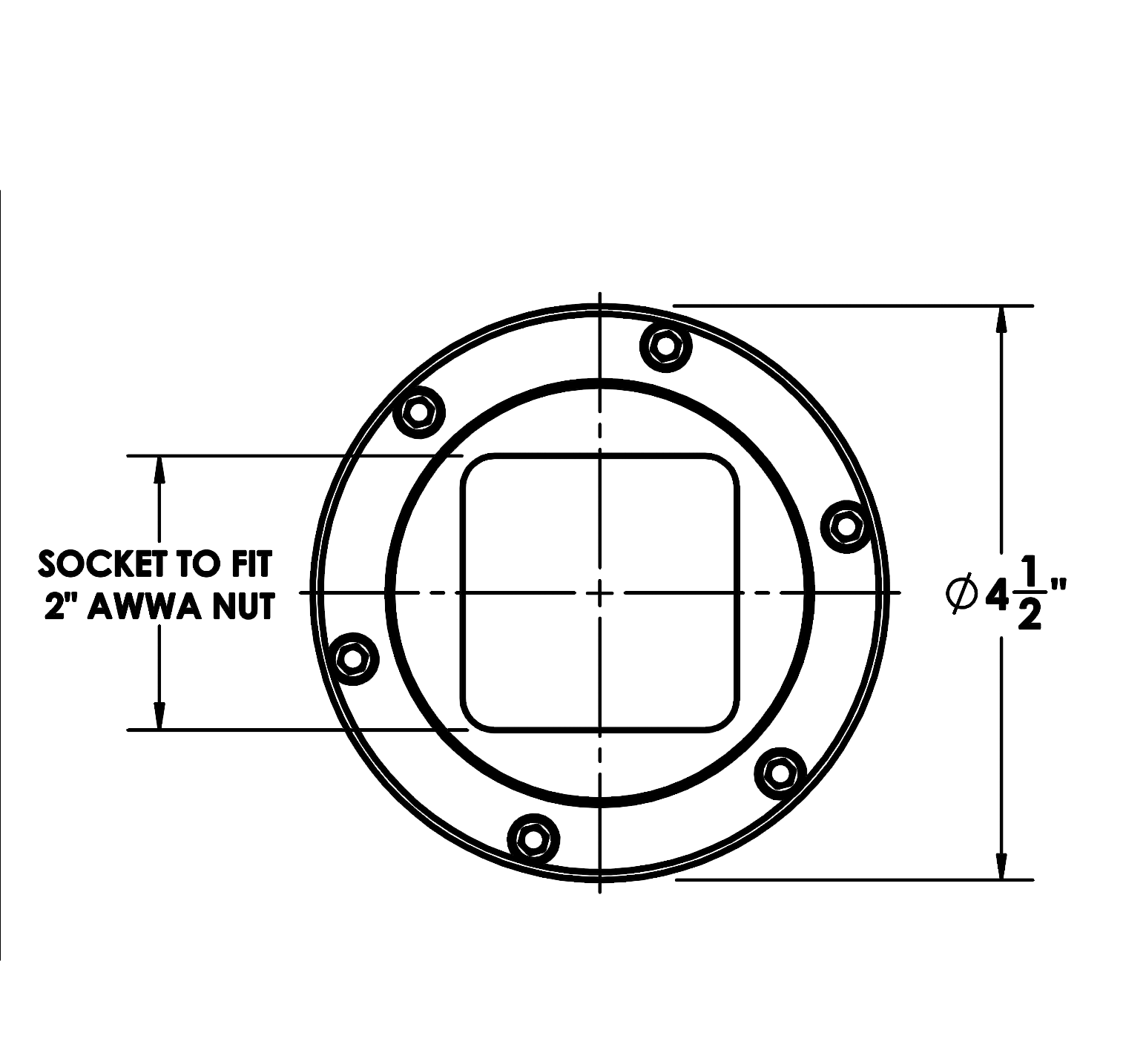

- Female connection: Socket to fit 2" AWWA operating nut

- Weight: 12 lbs

- Operating Temperature: -10°F to 250°F

- Envelope Dimensions: 6-1/2" x ⌽4-1/2"

- IP Rating: Exceeds IP68. Tested water-tight under 230 feet water pressure

*higher & lower temperature models are available

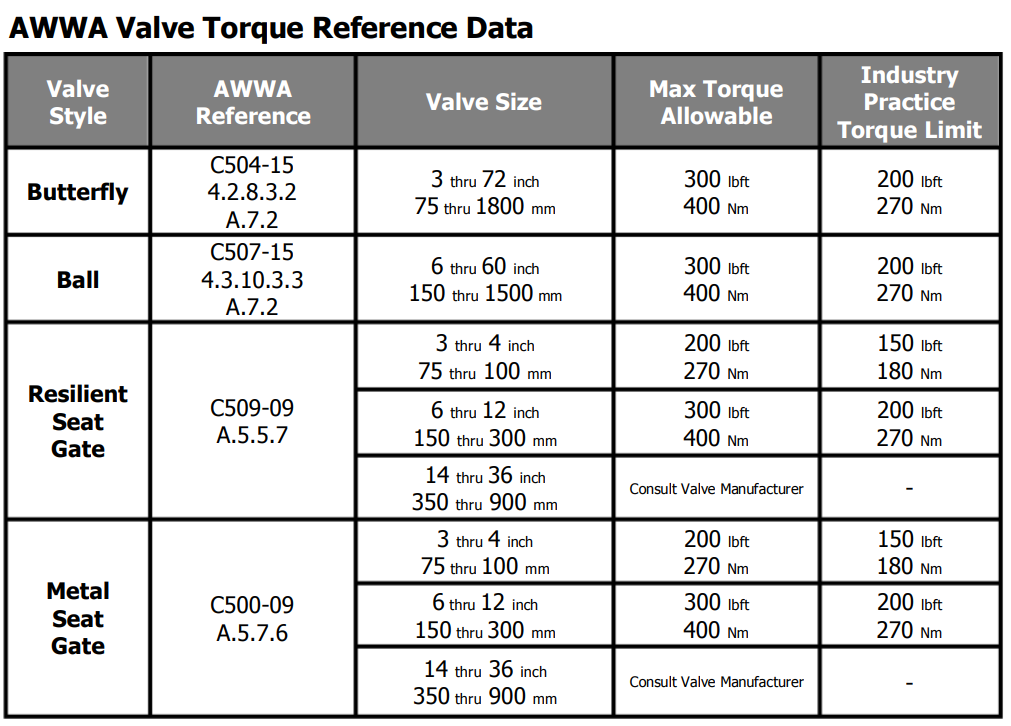

| Model | Standard Trip Torque | Trip Torque Capacities |

|---|---|---|

| D86-250 | 200 lbft | 25 to 250 lbft |

| D86-500 | 400 lbft | 50 to 500 lbft |

*Other trip-torques are available

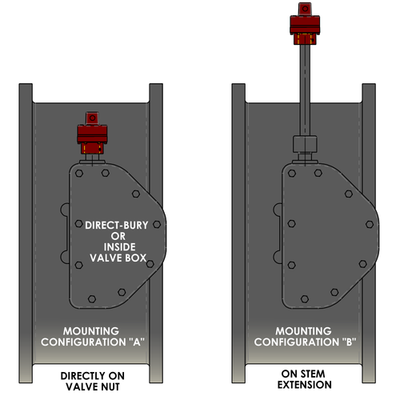

Mounting

Place the Model D86 Valve Overtorque Clutch™ on the 2" AWWA operating nut and tighten the two mounting screws.

Buried Valve

To mount on buried valve, hook into the drain hole in the side of the D86 nut then lower the unit onto the valve nut. The mounting screws need not be tightened.

Calibration

Model D86’s are shipped pre-calibrated to end-user specification and ready to install.

The trip torque calibration screws

are sealed and concealed to prevent tampering.

They may be re-calibrated by the following procedure:

- Remove polyurethane sealant from bonnet nut cavity to expose the calibration screw.

- Rotate the adjusting screw inward (clockwise) to increase trip torque or outward (counterclockwise) to decrease. 1/16 revolution will change the trip torque approximately 12 pounds feet for D86-250, and 24 pounds feet for D86-500. For more precise calibration use a torque wrench to verify setting.

- After adjustment, fill nut cavity with Devcon Flexane 94 liquid polyurethane up to the lower edge of the drain hole in the side of the D86 nut.

Model D86

Overtorque Clutch

Features

- Zero maintenance

- Operates buried & submerged

- Permanently lubricated

- Hermetically sealed

- Pre-calibrated & ready to mount, no modifications required

- Corrosion protected with AWWA C213-approved fusion-bonded epoxy & stainless-steel fasteners

Fully Submersible

The Model D86 operates buried and submerged. The mechanism is permanently lubricated and hermetically sealed to exceed IP 68 water ingress standard IEC 60529 Ed 2.2 2013. Units have been tested water tight under 230 feet (70 meters) water pressure.

ZERO Maintenance

The D86 requires ZERO maintenance due to it's permanently sealed & lubricated mechanism.

Decades of Reliable Use

Most large municipalities across the US have been using the Model D86 for decades.

Rugged. Dependable.

Rugged construction materials, corrosion protected by industry standard AWWA C213-approved 3M fusion-bonded epoxy.